Earthwatcher's photos with the keyword: coke ovens

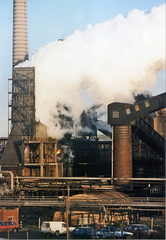

Orgeave Coke Ovens 1988

| 18 Jul 2006 |

|

Coal from Orgreave Colliery was taken directly into the adjacent British Steel coke ovens to make metallurgical coke for the steel industry. There was also an extensive coal by-products chemical works at the same site.

When the wind was in an unfavourable direction, it blew the fumes from the coke ovens straight over the colliery downcast shaft where the smell was quickly spread all round the mine workings underground.

Orgreave Colliery ceased production in 1981, but coal from nearby Treeton colliery was transported by conveyor to the coke ovens.

Coke ovens 3

| 28 Jun 2006 |

|

Coal from Brookhouse Colliery was made into coke at the adjacent coke ovens.

Rams push the red-hot coke into a hopper mounted on rails. The hopper is electrically driven - you can see the locomotive and its electric pickup - and is transported a few tens of metres away to the cooling area where jets of water are sprayed onto the coke to cool it. It is then loaded into lorries or wagons to go to the steel works.

The coke ovens were closed and dismantled in the late 1980s. The land was opencasted to recover the shallow coal and then restored to make the Rother Valley Country Park.

Coke ovens 2

| 28 Jun 2006 |

|

Coal from Brookhouse Colliery was made into coke at the adjacent coke ovens.

Rams push the red-hot coke into a hopper mounted on rails. The hopper is electrically driven (via the pair of overhead wires in the centre of the picture) and is transported a few tens of metres away to the cooling area where jets of water are sprayed onto the coke to cool it. It is then loaded into lorries or wagons to go to the steel works.

The coke ovens were closed and dismantled in the late 1980s. The land was opencasted to recover the shallow coal and then restored to make the Rother Valley Country Park.

Coke ovens 1

| 28 Jun 2006 |

|

Coal from Brookhouse Colliery was made into coke at the adjacent coke ovens.

Rams push the red-hot coke into a hopper mounted on rails. The hopper is electrically driven (via the pair of overhead wires in the centre of the picture) and is transported a few tens of metres away to the cooling area where jets of water are sprayed onto the coke to cool it. It is then loaded into lorries to go to the steel works.

The coke ovens were closed and dismantled in the late 1980s. The land was opencasted to recover the shallow coal and then restored to make the Rother Valley Country Park.

Jump to top

RSS feed- Earthwatcher's latest photos with "coke ovens" - Photos

- ipernity © 2007-2025

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

Twitter