Coal Mining

That tell-tale orange stream

| |

|

It draws your eye to the brick-lined tunnel from which the ochrey water is running. Norbury Colliery pumping adit outlet is discharging minewater that has risen up the shaft of the pumping pit from a depth of around 900ft. The colliery closed in 1892.

Beehive oven - Aspen Colliery

| |

|

Interior of one of the surviving beehive coke ovens at the site of Aspen Colliery near Burnley. The colliery closed in 1922 so the survival of these ovens is remarkable.

Welbeck Colliery closes

| |

|

www.chad.co.uk/news/Welbeck-Colliery-to-close-next.627172...

It is the end of an era at Welbeck Colliery as the pit prepares to cease production next Tuesday after almost a century. UK Coal has announced the colliery, at Meden Vale, will be closed on 11th May when the last coal face there reaches the end of its life, after being open since 1912.

The colliery had 1,400 working men at its peak but this figure has now fallen to 410 – all of whom were offered jobs in other parts of the company. Around 170 workers have finished working at the colliery so far, with just 57 taking voluntary redundancy.

And about 70 men will remain working there for the next three months to recover face equipment worth around £6m, some of which will be transferred to neighbouring Thoresby Colliery, then the pit will be decommissioned.

UK Coal spokesman Stuart Oliver said: "Most of the site is owned by Welbeck Estates and there are on-going discussions involving Welbeck Estates, UK Coal, the local authority and other job-creation agencies to determine what the best future use of the site should be to create jobs for the future."

The first shaft for the pit was sunk between 1912-15 at a depth of 660m and it became one of the first million-tonne-a-year superpits.

Mr Oliver said the colliery shared the same seam of coal with Thoresby Colliery, the deep soft seam, but it is separated by a geological fault, so the company decided to continue mining it from the Thoresby side.

He said: "When the decision to close it was taken about three years ago, it had a limited future, for the coal reserves on this side of the geological fault."

The coal face at Welbeck is 300m long and is now reaching the end of its life, while Thoresby Colliery has had a £55m investment made to open up new reserves there, which will keep it open for at least another decade.

The sump

| |

|

Down the drift was the sump where water collected before being pumped from the mine.

Caphouse Colliery

| |

|

I think that the view of Caphouse Colliery from the roadside has plenty of atmosphere, particularly when it is wet and gloomy like here.

Coal breakers

| |

|

The coal extracted at the Sandaoling opencast mine is brought to an unloading point at the washery near the town where it is tipped onto a bar screen over the bunkers. Two cranes with steel 'D' shaped weights are then used to break up the oversize lumps so that they can fall through before being conveyed into the washery. This train is part way through unloading and the breakers are in use as one of the loaded wagons is tipped.

Qikeng Mine

| |

|

Small colliery connected to the Lishu system of the Jixi Coal Railways. At this time one or two trains a day were loading under the bunkers where the blue lorry stands but since then the mine has closed and the tracks have been lifted.

Fallen from the roof

| |

|

Dodgy roof timbers and a large piece of stone that has fallen from the roof inside this nineteenth century colliery adit on the Lancashire moors. This mine was probably opened after 1850 and was certainly abandoned by 1890.

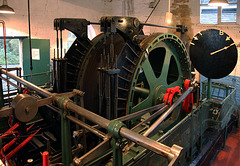

Colliery winder

| |

|

Steam winding engine and drum at Caphouse Colliery, built in 1876 by Davy Bros Ltd, Sheffield. This wound coal until 1974 and continued in use for shaft inspections until 1979. It is very small for colliery use and the shaft capacity was only 33 tons per hour. This led to the driving of a drift to enable output to be significantly increased.

Today the engine is preserved as part of the National Coal Mining Museum which is based at the colliery. It no longer winds the shaft as a modern electric winder is used to take visitors underground.

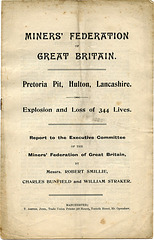

Pretoria Pit explosion - Report to the Miners' Fed…

| |

|

Another document from the Tarchives

The explosion at Pretoria Pit occurred on 21st December 1910 and was the second worst mining accident in England, and the third worst in Britain. The recent centenary of this tragic event has recently been marked by the publication of an excellent book by Alan Davies .

The document in my collection is a report by three representatives of the Miners' Federation of Great Britain who were deputed by that body to act as its representatives at the inquest into the deaths, and subsequent public inquiry into the explosion. Their report reflects the findings of the inquiry and makes a number of comments regarding the operation and supervision of the colliery and concludes in calling for alterations to the relevant Mines' Act.

The document came into my possession from the boardroom of the Poynton Co-operative Society shortly before the building was demolished. I was given a selection of records relating to the Co-operative Society in Poynton and also the Poynton Collieries branch of the Lancashire and Cheshire Miners' Federation that at one time met there. I presume that every branch was sent a copy of the report.

Kellingley Colliery

| |

|

Often referred to as the 'Big K', the Kellingley pit was sunk between 1958 and 1965 when the first coal was raised. The No.1 shaft on the left is 791m deep and is used for man riding and materials. The upcast is 768m deep and can raise coal at up to 900 tonnes per hour. Coal is mainly supplied to local power stations with a small amount of house coal also produced.

Daw Mill sidings

| |

|

Not much action in the loading sidings at Daw Mill Colliery on this particular sunday.

Daw Mill

| |

|

Downcast shaft at Daw Mill colliery in Warwickshire. This is the largest colliery in the UK, mining a five-metre thick section of the Warwickshire Thick seam some 750 metres below the ground. The shafts here are 558 metres and 556 metres deep. In 1982, a drift was completed and all coal is now brought out this way.

Butterley Park - West Pit

| |

|

As far as I can tell this is the West Pit of the Butterley Park Colliery of the Butterley Company at Swanwick. Today it stands with adjacent engine house in the middle of a farm park where visitors can feed and watch a range of animals. I think that the colliery was open from 1848 to 1946 with the main shaft known as Britain Pit.

Mining relic

| |

|

The landowner advised me that there had once been an adit from which the Sweet seam was worked above Commonside in Macclesfield. This is likely to have been in the mid-nineteenth century and there is little left of the entrance. However, a short distance away this piece of wrought iron bridge rail is a tangible survivor of the mine.

Roof problems

Sough

| |

|

This colliery sough dates from c1798 and runs for about 550 metres, draining an area of coal that was worked from at least three shafts until closure towards the end of the nineteenth century. The water level is artificially high due to a collapse creating a dam.

Steam and spoil

| |

|

The afternoon passenger service passing one of the spoil heaps at the Fuli mine on the Hegang Coal Railway. The figure on the top is one of the coal pickers who make a living sorting through the waste as it is tipped.

Jump to top

RSS feed- Latest items - Subscribe to the latest items added to this album

- ipernity © 2007-2025

- Help & Contact

|

Club news

|

About ipernity

|

History |

ipernity Club & Prices |

Guide of good conduct

Donate | Group guidelines | Privacy policy | Terms of use | Statutes | In memoria -

Facebook

Twitter